CASE STUDY

Manufacturing Demand Planning App

We cure your digital pain with cutting-edge programming solutions so you can increase your profits.

Overview

This project focused on improving demand planning and supply logistics in a manufacturing plant. Our goal was two-fold: make it easy to plan labor shifts as well as to eliminate production stoppages. Our plan was to do this by replacing an error-prone spreadsheet with an automated planning desktop app.

Challenge

Our client, a manufacturing facility, was having trouble getting their NetSuite ERP software to cooperate. Their first attempt at fixing the issue had them relying on a highly complex spreadsheet which proved to be more trouble than it was worth. A recent move to a new facility had caused it to fall out of sync with their manufacturing process and it was now too difficult to track lead times and crew shifts. As a result, production shortages became the new normal.

Solution

Diabase built a desktop application that interfaced with the existing NetSuite ERP database. It was split into two views. The first listed each individual SKU and did the following:

The app told the client how much to produce per month based on forecasted sales data.

The user could edit any month’s values and the app would automatically calculate all the future months for them, making it easy to plan ahead.

It displayed helpful error messages when there was going to be a production stoppage.

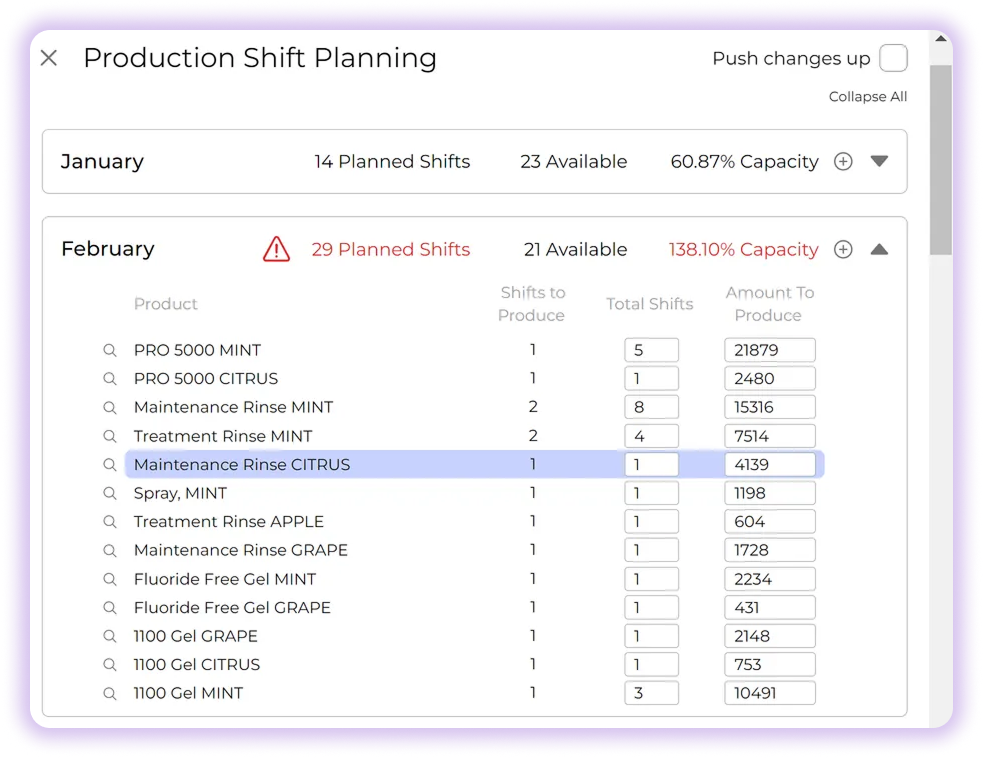

The second view in the software displayed the same data but in a different way. This was designed for planning the number of labor shifts needed per month in order to fulfill quotas.

It automatically pulled values from the first view that listed the SKUs. Any changes the client made would be kept track of and updated in the first view.

The client could make changes to the number of labor shifts per SKU, and it would calculate the total labor capacity for the month.

Once again, it automatically calculated future months, making it easy to plan ahead.

By making it simple to plan for the future and keeping track of complicated changes, the software empowered the supply chain and logistics department– greatly simplifying their process.

Outcome

The new system simplified demand planning, supply logistics, and production labor shift planning. It provided crucial insight into the future by doing the hard mental work that the client used to have to do by hand. The overall result was a major reduction in production stoppages, as well as ensuring each month’s labor capacity was near 100% in order to produce everything needed.

This project reflects our philosophy at Diabase, that software should be beautiful, intuitive, and reliable - built for the people who do the work, not against them.

By replacing an old, complicated spreadsheet and interfacing with the existing database, we helped this manufacturer run with much greater efficiency.

Let’s Streamline Your Operations

Tell us a little about your project, and we’ll show you how Diabase can make your data work harder for you.